The selection of appropriate PLG supplies is crucial for optimizing workflow and ensuring compliance with industry regulations. This document outlines essential equipment and safety measures that must be integrated into daily operations. Additionally, it presents 25 best practices to enhance the effectiveness of PLG supplies in various industrial settings, enabling a safer and more productive environment. Implementing these guidelines will significantly improve operational outcomes and reduce risks associated with industrial processes.

We’ll cover the most critical PLG supplies that keep your operations running smoothly. You’ll learn about essential safety equipment that protects your workforce and facilities from potential hazards. We’ll also explore precision measurement tools that help you monitor system performance and maintain quality standards.

The following breakdown includes high-capacity storage solutions, advanced transfer equipment, and professional-grade installation tools. Plus, we’ll share proven procurement strategies to help you source quality PLG supplies while managing costs effectively.

Essential PLG Supplies for Heavy Manufacturing Operations

High-Performance Industrial Lubricants for Maximum Equipment Efficiency

Modern heavy manufacturing demands lubricants that can withstand extreme pressures, temperatures, and operating conditions. Synthetic gear oils represent the gold standard for industrial applications, offering superior thermal stability and extended drain intervals compared to conventional petroleum-based products. These advanced formulations resist oxidation at temperatures exceeding 250°F while maintaining consistent viscosity across wide temperature ranges.

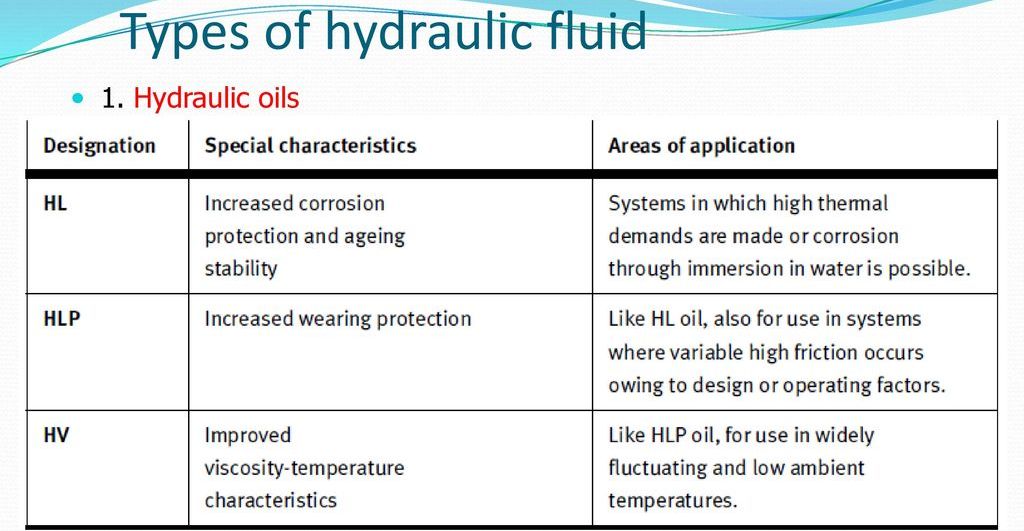

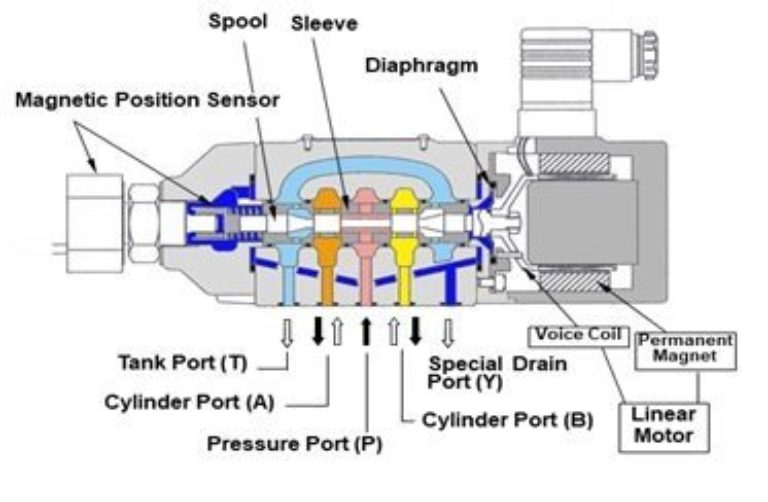

Heavy-duty hydraulic fluids deserve equal attention in manufacturing operations. Anti-wear hydraulic oils with zinc-based additives protect critical pump components while providing excellent filterability and water separation properties. For high-pressure systems operating above 3000 PSI, consider premium fluids with enhanced shear stability ratings.

Bearing and chain lubricants require specific attention to application methods. Food-grade options meet NSF H1 requirements for facilities processing consumables, while extreme pressure greases handle shock loading in mining and steel production environments. Automatic lubrication systems ensure consistent application intervals, reducing maintenance costs and equipment downtime.

| Lubricant Type | Temperature Range | Key Benefits | Typical Applications |

|---|---|---|---|

| Synthetic Gear Oil | -40°F to 300°F | Extended life, energy efficiency | Gearboxes, reducers |

| Anti-wear Hydraulic | -10°F to 250°F | Component protection | Hydraulic systems |

| EP Grease | -20°F to 350°F | Shock resistance | Bearings, chains |

Heavy-Duty Sealing Solutions for Leak Prevention

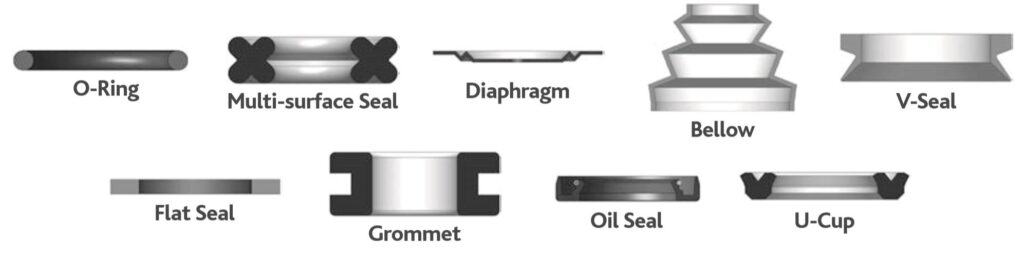

Elastomeric seals form the backbone of leak prevention in industrial PLG systems. Nitrile (NBR) compounds excel in petroleum-based applications, offering excellent resistance to oils and fuels at moderate temperatures. For high-temperature environments exceeding 200°F, fluoroelastomer (FKM) seals provide superior chemical resistance and thermal stability, though at higher costs.

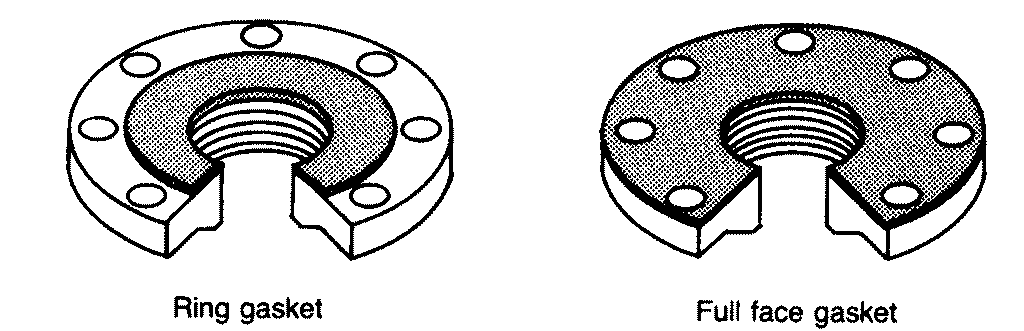

O-rings and gaskets require proper groove design and installation techniques. Standard AS568 sizing ensures compatibility across manufacturers, while custom molded seals accommodate unique housing geometries. Dynamic applications demand careful consideration of durometer hardness – softer compounds (70-80 Shore A) seal better but wear faster than harder materials (85-95 Shore A).

Mechanical seals represent critical components in pump and rotating equipment. Cartridge-style seals simplify installation and reduce maintenance time compared to component seals. Carbon-ceramic face combinations handle most industrial fluids, while silicon carbide faces excel in abrasive applications. Proper flush plans prevent seal face damage from dry running or contamination.

Thread sealants and gasket compounds provide additional sealing options for threaded connections and flange joints. Anaerobic sealants cure in the absence of air, creating permanent seals for hydraulic fittings. PTFE tape remains popular for removable connections, though proper wrapping technique prevents over-tightening and thread damage.

Professional-Grade Cleaning Compounds for Optimal Maintenance

Solvent-based degreasers cut through heavy hydrocarbon contamination on equipment surfaces and components. Chlorinated solvents provide aggressive cleaning action but require proper ventilation and waste disposal procedures. Safer alternatives include d-limonene-based cleaners derived from citrus oils, offering similar degreasing power with reduced environmental impact.

Alkaline cleaners excel at removing proteinaceous soils and burnt-on deposits from heat exchangers and process equipment. Concentrated formulations allow dilution ratios up to 1:50, reducing storage requirements and transportation costs. Hot tank cleaning systems maximize effectiveness by maintaining solution temperatures between 140-180°F.

Parts washing systems automate cleaning processes while containing solvents and waste streams. Spray cabinet washers handle small components efficiently, while immersion tanks accommodate larger parts requiring extended soak times. Solvent recovery through distillation reduces operating costs and environmental impact.

Specialty cleaning products address specific contamination types. Rust removal compounds containing phosphoric acid convert iron oxides to water-soluble salts without damaging base metals. Scale removers tackle mineral deposits in cooling systems and heat exchangers. Enzyme-based cleaners break down organic matter in wastewater treatment applications.

| Cleaner Type | Dilution Ratio | Best Applications | Safety Considerations |

|---|---|---|---|

| Chlorinated Solvent | Ready-to-use | Heavy grease removal | Requires ventilation |

| Alkaline Cleaner | 1:10 to 1:50 | General degreasing | Caustic – wear PPE |

| Citrus Degreaser | 1:5 to 1:20 | Light to medium soils | Low toxicity |

Critical Safety Equipment for Industrial PLG Handling

Advanced Personal Protective Equipment for Worker Protection

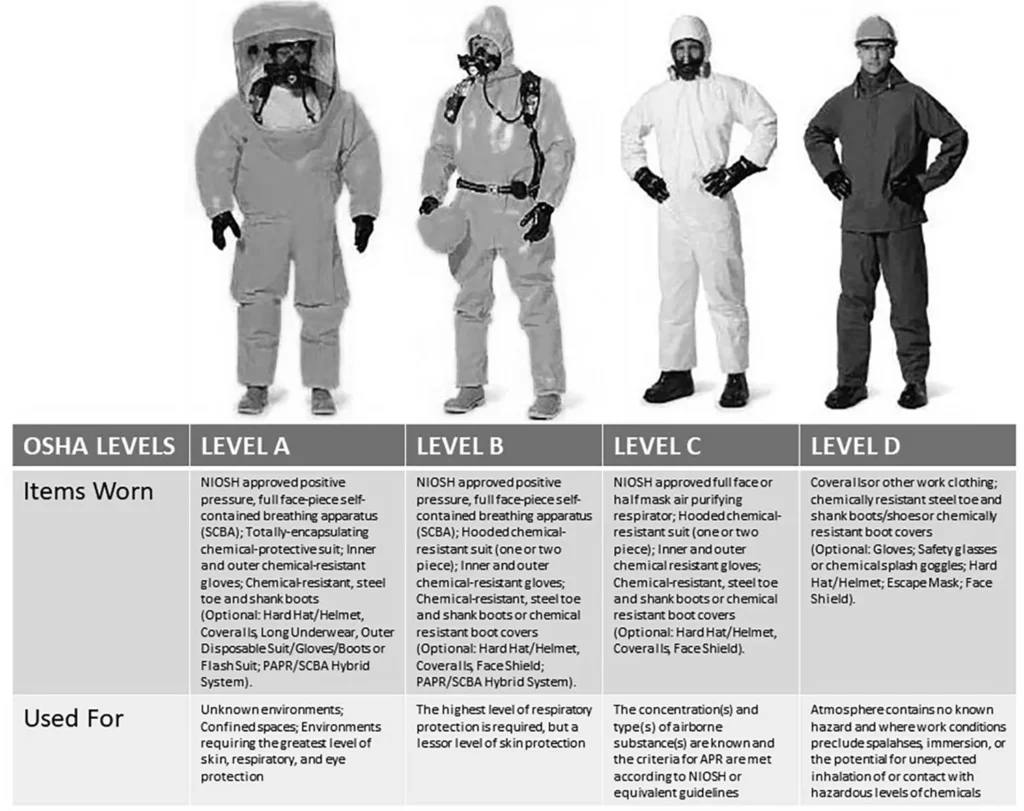

Working with PLG in industrial settings demands specialized protective gear that goes beyond standard safety equipment.

Chemical-resistant suits made from materials like Tychem or Chemmax provide full-body protection against splash hazards and vapor exposure. These suits feature sealed seams and integrated boot systems to prevent any skin contact with hazardous substances.

Respiratory protection requires careful selection based on PLG concentration levels. Self-contained

breathing apparatus (SCBA) units offer maximum protection in high-risk environments, while air-purifying

respirators with appropriate cartridges work well for routine maintenance tasks. Full-face respirators

provide eye protection alongside respiratory safety, crucial when dealing with volatile PLG compounds.

Hand protection involves multiple layers – chemical-resistant inner gloves paired with puncture-resistant outer gloves. Nitrile and neoprene materials offer excellent chemical resistance, while cut-resistant linings protect against sharp edges on equipment. Emergency escape breathing devices should be readily accessible to all workers, providing 10-15 minutes of breathable air during evacuation scenarios.

Eye and face protection extends beyond basic safety glasses to include chemical splash goggles and face shields designed specifically for hazardous material handling. Anti-fog coatings and ventilation systems maintain clear vision during extended use.

Emergency Response Systems for Hazardous Situations

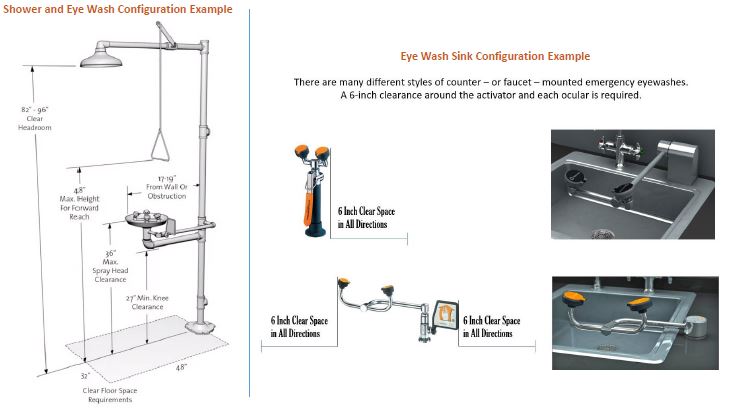

Emergency shower and eyewash stations must be strategically positioned within 10 seconds of any PLG handling area. These systems require immediate access to copious amounts of clean water – typically 20 gallons per minute for shower stations and 0.4 gallons per minute for eyewash units. Heated systems prevent thermal shock in cold environments while maintaining proper flow rates.

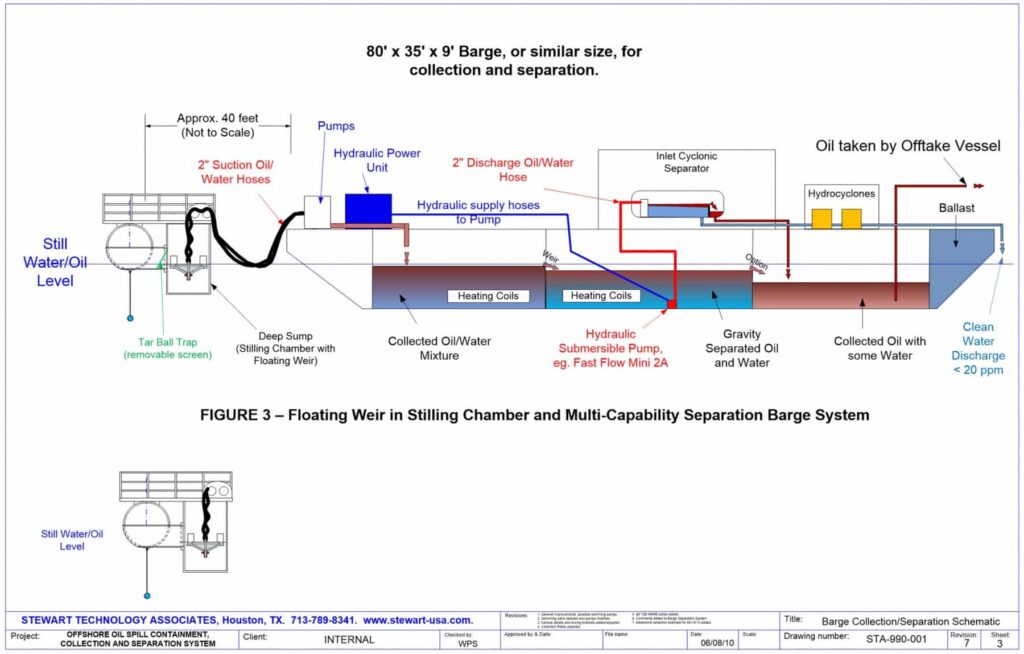

Spill containment systems include portable berms, absorbent materials specifically designed for PLG compounds, and emergency plugging devices. Spill response kits should contain non-reactive absorbents, neutralizing agents where appropriate, and specialized cleanup tools that won’t create sparks or static electricity.

Communication systems enable immediate contact with emergency services and facility management. Two-way radios with intrinsically safe designs prevent ignition risks, while emergency alarm systems alert all personnel to evacuation procedures. Gas detection alarms connected to these communication networks provide automated emergency notifications.

Decontamination stations allow for immediate cleaning of personnel and equipment exposed to PLG materials. These systems include multiple wash stages, from initial gross decontamination through final rinse cycles, with appropriate drainage systems that prevent cross-contamination.

Automated Safety Monitoring Tools for Continuous Protection

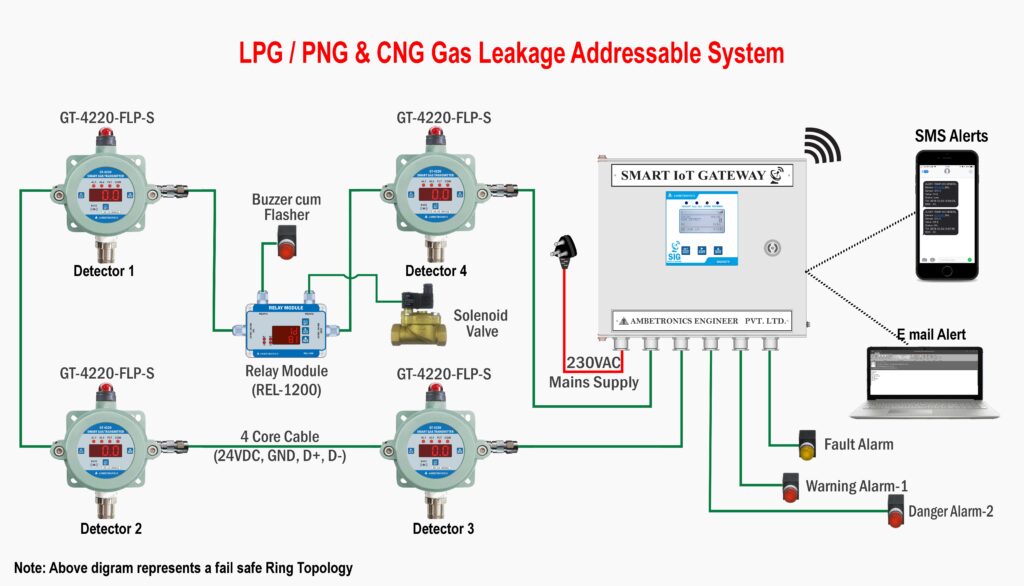

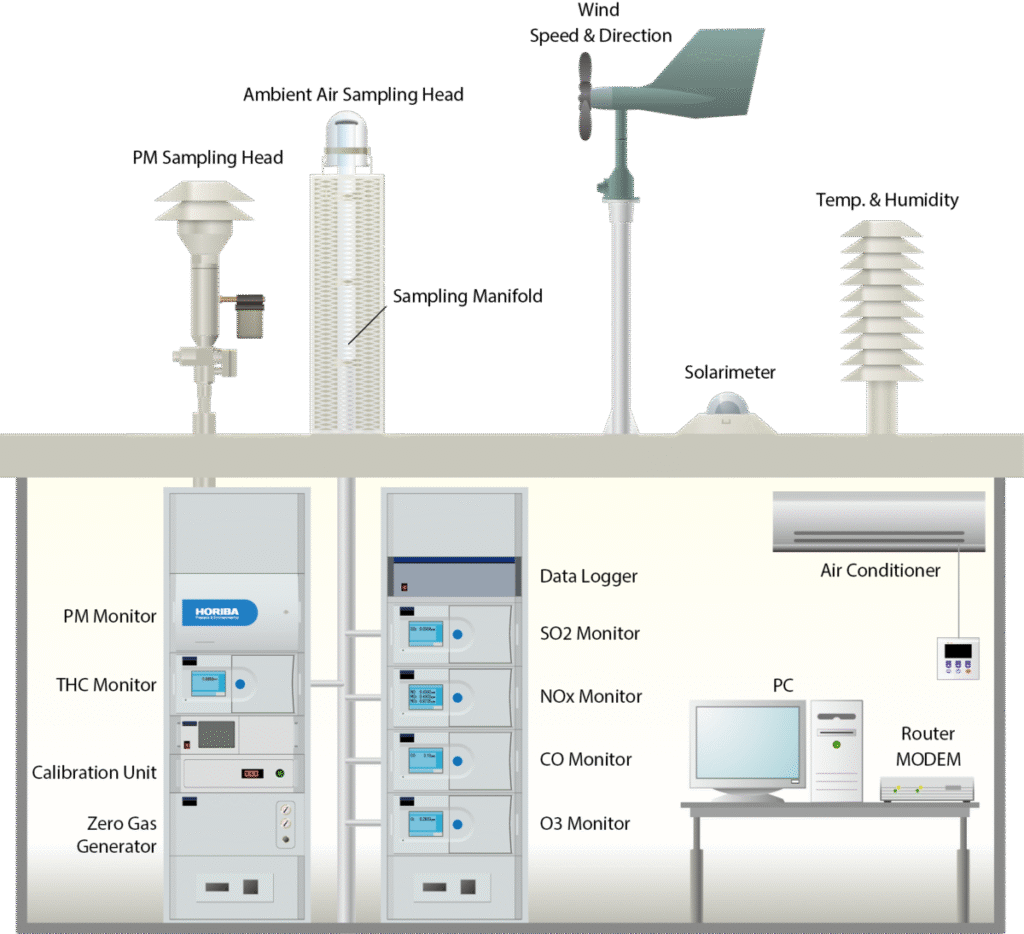

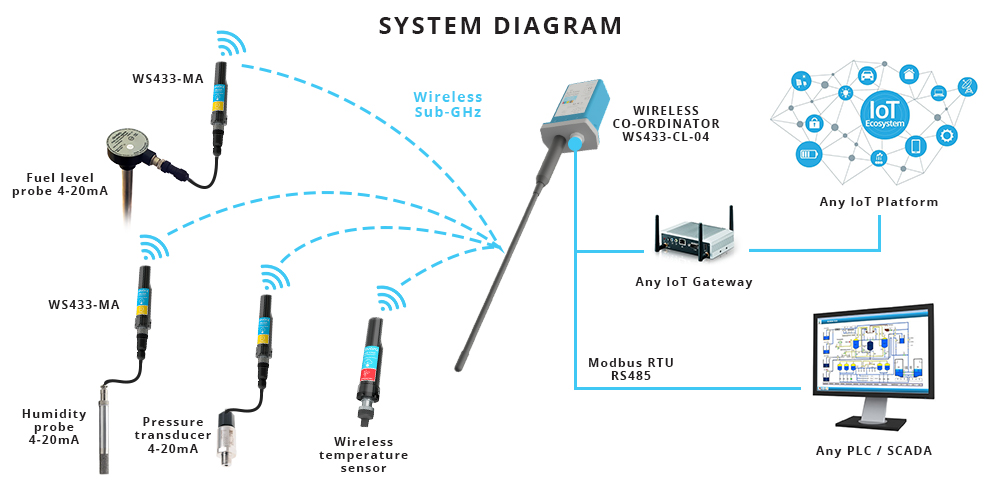

Real-time gas detection systems provide continuous monitoring of PLG vapors and potential leak sources. Multi-point detection networks use wireless sensors to monitor large facility areas, transmitting data to centralized control systems. These sensors detect concentrations well below dangerous levels, typically at 10% of the lower explosive limit (LEL).

Atmospheric monitoring equipment tracks oxygen levels alongside toxic gas concentrations. Confined space monitors provide portable detection capabilities for maintenance work, while fixed monitoring systems offer permanent surveillance of process areas. Smart sensors integrate with facility management systems to provide automated responses to dangerous conditions.

Temperature and pressure monitoring systems track equipment performance and identify potential failure points before they become safety hazards. Thermal imaging cameras detect hot spots that might indicate equipment malfunction or fire risks, while pressure transducers monitor system integrity.

Environmental monitoring extends beyond the immediate work area to include ambient air quality, groundwater monitoring, and soil contamination detection. These systems help identify potential environmental impacts and ensure regulatory compliance.

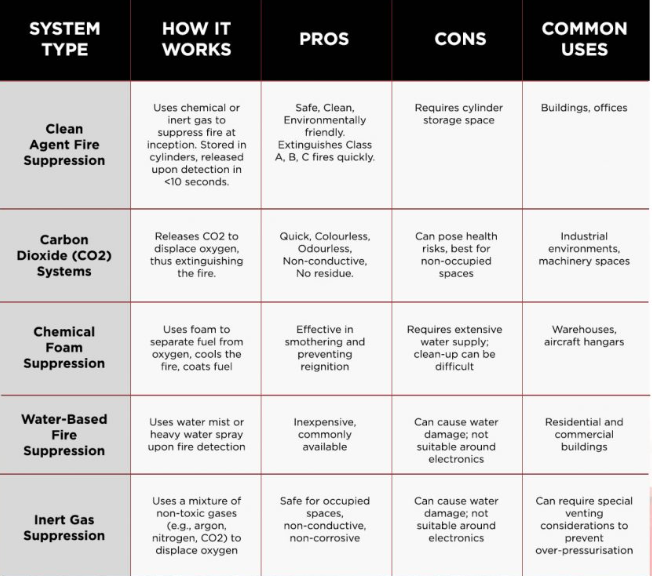

Fire Suppression Systems Designed for PLG Environments

Specialized fire suppression systems address the unique challenges of PLG-related fires. Dry chemical systems using sodium bicarbonate or potassium bicarbonate effectively suppress Class B fires involving flammable liquids. These systems deploy quickly and leave minimal residue compared to traditional foam systems.

Carbon dioxide suppression systems work well in enclosed spaces where PLG vapors might accumulate. Total flooding systems provide complete fire suppression while minimizing damage to sensitive equipment. Local application systems target specific high-risk areas like pump stations or transfer points.

Water spray systems designed for PLG facilities use special nozzles that create fine mist patterns, cooling surfaces and diluting vapor concentrations without spreading burning liquids. Deluge systems activate automatically when heat or flame detection systems trigger, providing immediate area protection.

Explosion suppression systems detect pressure rises in milliseconds and inject suppression agents before destructive pressure levels develop. These systems protect enclosed process equipment and prevent secondary explosions that could affect larger facility areas.

Precision Measurement and Testing Instruments

Digital Flow Meters for Accurate Volume Control

Modern industrial operations demand precise liquid petroleum gas (LPG) flow measurement to maintain operational efficiency and regulatory compliance. Digital flow meters represent the gold standard for volume control in PLG applications, offering real-time data acquisition and superior accuracy compared to traditional mechanical alternatives.

Coriolis mass flow meters excel in PLG environments, providing direct mass measurement regardless of temperature and pressure variations. These instruments typically achieve accuracy levels of ±0.1% to ±0.5%, making them ideal for custody transfer applications where precise billing matters. Their ability to measure density simultaneously allows operators to detect product quality changes instantly.

Turbine flow meters offer excellent repeatability for clean PLG streams, with minimal pressure drop across the measurement point. Their digital outputs integrate seamlessly with SCADA systems, enabling automated control and data logging. For high-viscosity applications or when particulates may be present, positive displacement meters provide reliable measurement with built-in temperature compensation.

Installation considerations include proper upstream and downstream pipe lengths to ensure flow profile development. Regular calibration using certified reference standards maintains measurement integrity, while diagnostic capabilities in smart meters alert operators to potential issues before they affect accuracy.

Pressure Gauges for System Monitoring

Reliable pressure monitoring forms the backbone of safe PLG operations, protecting equipment and personnel while optimizing system performance. Digital pressure gauges with data logging capabilities have largely replaced analog instruments in critical applications, offering enhanced accuracy and remote monitoring options.

Electronic pressure transmitters with 4-20mA outputs provide continuous monitoring for control room displays and automated safety systems. These devices typically feature accuracy ratings of ±0.25% full scale, with temperature compensation ensuring consistent readings across varying ambient conditions. Intrinsically safe designs meet hazardous area requirements for PLG installations.

For local monitoring, digital pressure gauges with large displays offer excellent visibility in harsh industrial environments. Battery-powered units eliminate wiring requirements while providing years of reliable operation. Many models include min/max recording functions and programmable alarms for critical pressure thresholds.

Pressure gauge selection depends on operating ranges, with different sensor technologies suited to specific applications:

| Pressure Range | Recommended Technology | Typical Accuracy |

|---|---|---|

| 0-100 psi | Silicon strain gauge | ±0.5% FS |

| 100-1000 psi | Stainless steel diaphragm | ±0.25% FS |

| 1000+ psi | Thin film strain gauge | ±0.1% FS |

Regular calibration against NIST-traceable standards ensures measurement reliability, while proper installation with isolation valves and snubbers protects against pressure spikes.

Quality Testing Kits for Product Verification

Product quality verification ensures PLG meets specifications and regulatory standards throughout storage, handling, and distribution processes. Portable testing kits enable on-site analysis without laboratory delays, supporting rapid decision-making in operational environments.

Hydrocarbon composition analyzers determine propane, butane, and other component percentages using gas chromatography principles. Modern portable units complete analysis cycles in minutes, displaying results on color touchscreens with data storage capabilities. These instruments detect impurities that could affect combustion characteristics or downstream equipment performance.

Moisture content testing prevents corrosion and operational issues in PLG systems. Portable analyzers using electrolytic sensors provide accurate water content measurements down to parts-per-million levels. Regular moisture monitoring protects storage tanks, pipelines, and dispensing equipment from water-related damage.

Vapor pressure testing kits verify product volatility characteristics, ensuring safe handling and storage conditions. Digital instruments automatically compensate for temperature variations while providing results in multiple pressure units. This testing proves particularly important during seasonal transitions when ambient temperatures affect vapor pressure significantly.

Odor fade testing confirms mercaptan levels meet safety requirements for leak detection. Portable analyzers can detect these sulfur compounds at extremely low concentrations, ensuring adequate odorant levels throughout the distribution system. Regular testing prevents dangerous situations where gas leaks might go unnoticed due to insufficient odorization.

Sample collection equipment including heated sample cylinders, regulators, and safety accessories ensures representative samples for accurate analysis. Proper sampling techniques and equipment maintenance directly impact testing reliability and regulatory compliance.

High-Capacity Storage and Containment Systems

Industrial-Grade Tank Solutions for Bulk Storage

Steel and fiberglass tanks dominate industrial PLG storage, with capacities ranging from 500 to 50,000 gallons. Carbon steel tanks offer superior durability for most applications, while stainless steel variants handle corrosive materials. Double-wall construction provides built-in spill protection, eliminating the need for separate containment structures.

Tank selection depends on several factors:

- Volume requirements: Daily usage patterns and delivery schedules

- Material compatibility: Chemical resistance charts guide proper selection

- Pressure ratings: Atmospheric, low-pressure, or high-pressure specifications

- Temperature considerations: Insulation and heating elements for winter operations

Above-ground tanks simplify maintenance and inspection, while underground installations save space and reduce visual impact. Horizontal tanks work well for space-constrained facilities, while vertical designs maximize storage efficiency in smaller footprints.

Secondary Containment Systems for Environmental Protection

Environmental regulations mandate secondary containment systems that hold 110% of the primary storage capacity. Concrete containment areas, steel containment basins, and flexible liner systems each offer distinct advantages.

Concrete Containment Features:

- Permanent installation with 20+ year lifespan

- Chemical-resistant coatings prevent degradation

- Integrated drainage systems with manual or automatic valves

- Customizable dimensions for irregular spaces

Steel Containment Basins:

- Factory-fabricated for consistent quality

- Faster installation compared to concrete

- Relocatable if facility needs change

- Available with forklift pockets for positioning

Flexible liner systems work well for temporary installations or budget-conscious operations. Double-wall tanks eliminate separate containment needs while meeting regulatory requirements.

Temperature-Controlled Storage Units for Product Integrity

Many PLG products require specific temperature ranges to maintain quality and prevent degradation. Heated storage systems prevent crystallization and maintain proper viscosity for pumping operations.

Heating Options:

- Electric immersion heaters for precise control

- Steam coils for large-volume applications

- Glycol circulation systems for freeze protection

- Infrared heating panels for external warming

Insulation packages reduce energy costs and maintain consistent temperatures. Polyurethane foam insulation provides excellent thermal properties, while mineral wool offers fire resistance. Removable insulation jackets allow tank inspection without permanent removal.

Temperature monitoring systems track storage conditions and trigger alarms for deviations. Digital controllers integrate with facility automation systems for remote monitoring and data logging.

Automated Inventory Management Systems

Modern inventory management goes beyond simple level gauges. Automated systems track inventory levels, monitor product quality, and schedule deliveries based on usage patterns.

Key Components:

- Radar level transmitters for accurate measurement

- Product identification sensors for multiple products

- Flow meters tracking dispensing rates

- Tank gauging software with reporting capabilities

Wireless communication eliminates wiring costs while providing real-time data access. Cloud-based platforms allow remote monitoring from smartphones and computers. Integration with ERP systems streamlines purchasing and accounting processes.

Automated reorder systems maintain optimal inventory levels while preventing stockouts. Historical data analysis identifies usage trends and seasonal variations, enabling better planning and cost control.

Advanced Pumping and Transfer Equipment

Heavy-Duty Industrial Pumps for Efficient Product Movement

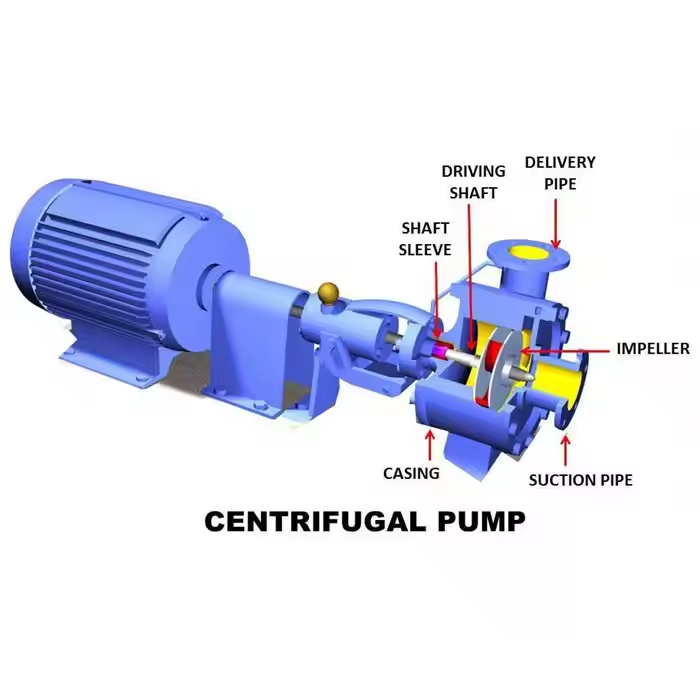

Centrifugal pumps stand as the workhorses of industrial PLG operations, delivering consistent flow rates up to 10,000 GPM while handling viscosities ranging from water-thin to heavy oils. These units feature corrosion-resistant materials like 316 stainless steel or specialized coatings that withstand aggressive chemical environments for decades.

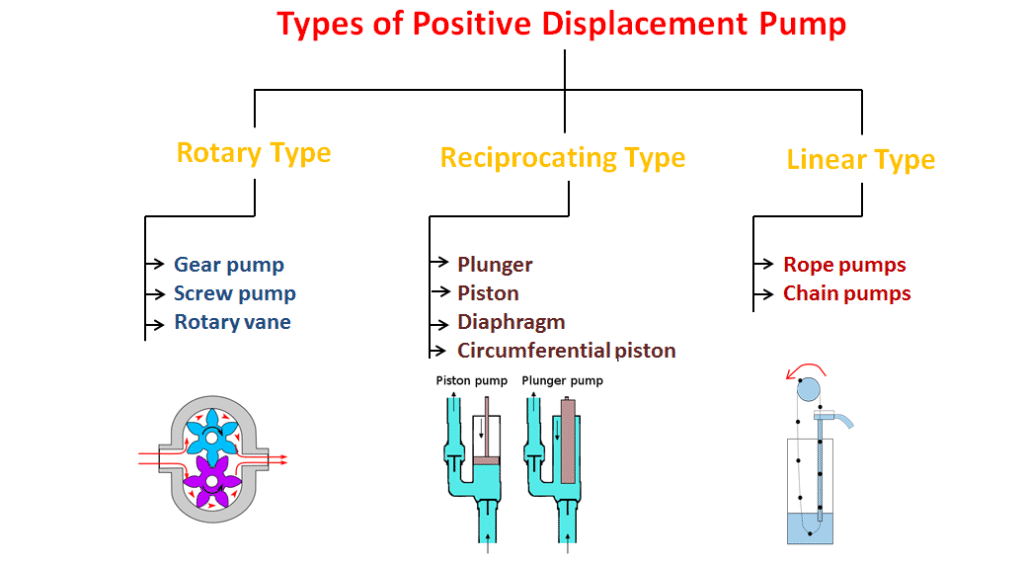

Positive displacement pumps excel when precise metering matters most. Gear pumps provide steady output regardless of back-pressure variations, while progressive cavity pumps handle shear-sensitive fluids without degradation. Diaphragm pumps offer containment advantages for hazardous materials, creating an air gap between the product and mechanical components.

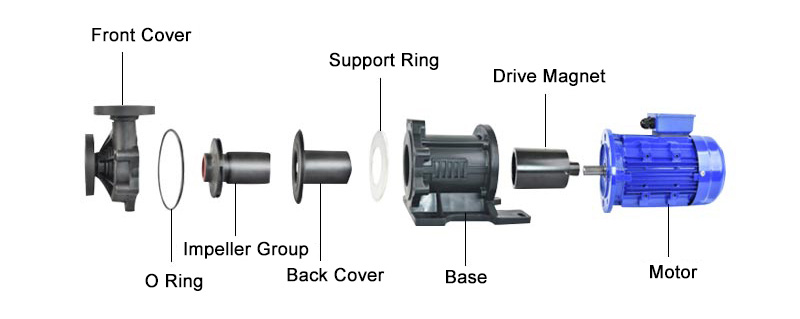

Magnetic drive pumps eliminate seal leakage entirely by using magnetic coupling instead of mechanical shaft seals. This design prevents environmental contamination and reduces maintenance costs significantly. Many facilities report 99.5% uptime with properly sized magnetic drive systems.

Specialized Transfer Hoses for Safe Handling

Chemical-resistant hoses must meet stringent standards like PTFE lining for aggressive solvents or conductive compounds for static dissipation. Wire-reinforced designs handle pressures exceeding 3,000 PSI while maintaining flexibility in sub-zero conditions.

Steam-cleaning compatibility extends hose life by allowing thorough sanitization between different product transfers. Quick-disconnect fittings with dry-break technology prevent spillage during connection changes, saving cleanup time and reducing waste.

Temperature ratings vary from cryogenic applications at -320°F to high-heat processes reaching 450°F. Double-wall construction provides secondary containment for critical applications where even minor leaks create safety hazards.

Automated Dispensing Systems for Precise Control

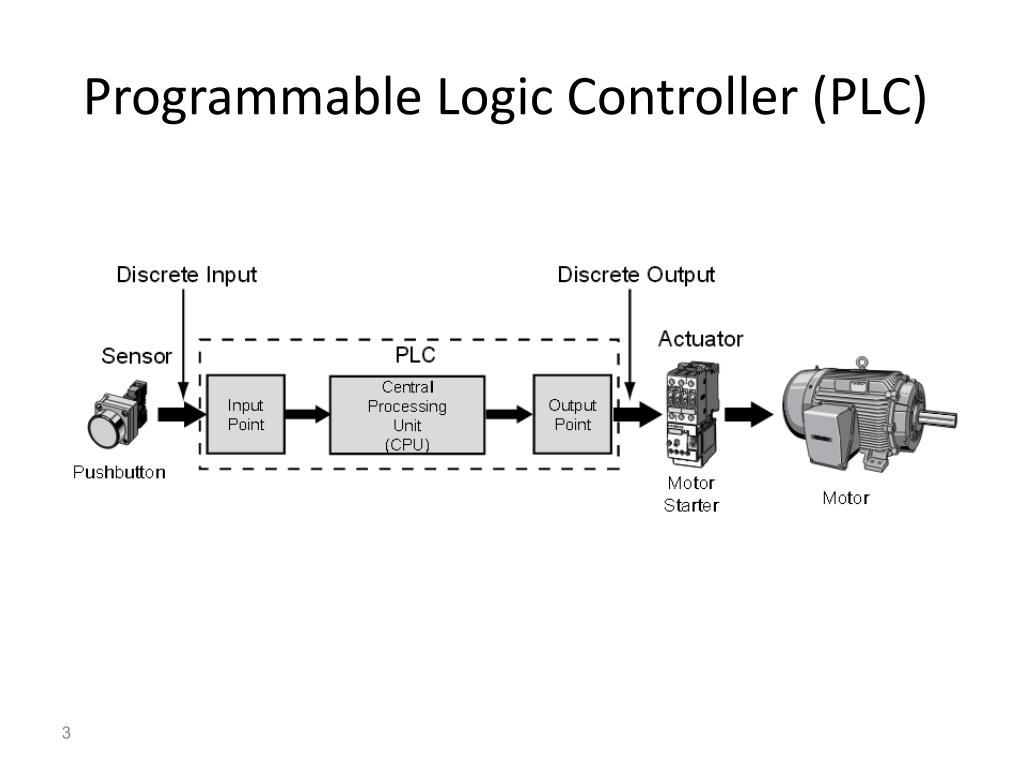

Programmable logic controllers (PLCs) integrate with load cells and flow meters to deliver accuracy within ±0.1% of target volumes. Recipe management software stores hundreds of formulations, ensuring consistent batch quality across multiple shifts.

Servo-driven metering valves respond in milliseconds, enabling real-time adjustments based on density variations or temperature changes. Vision systems verify fill levels and detect foam buildup that could affect measurement accuracy.

Bar code scanners link container identification to specific products, preventing cross-contamination errors. Operator interfaces display real-time data including flow rates, totalizers, and alarm conditions through intuitive touchscreen displays.

Filtration Units for Product Purity

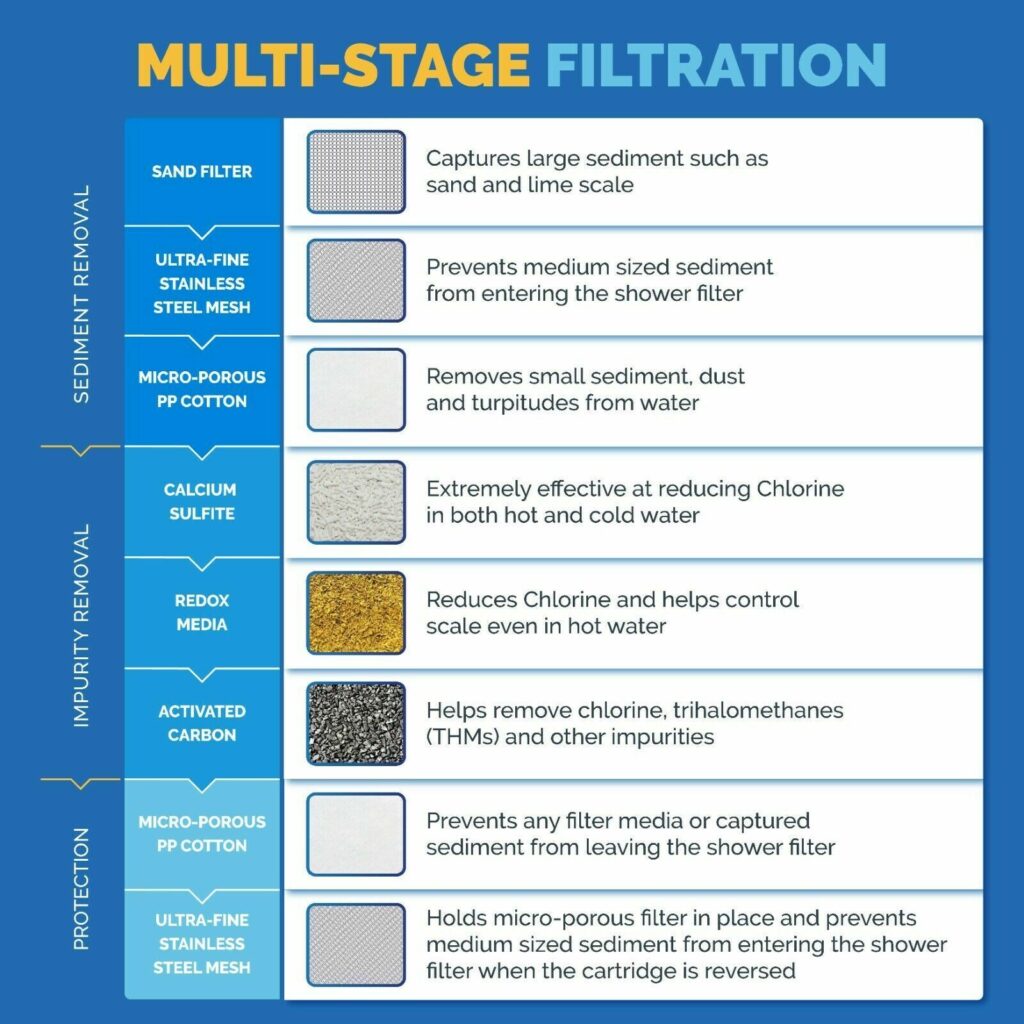

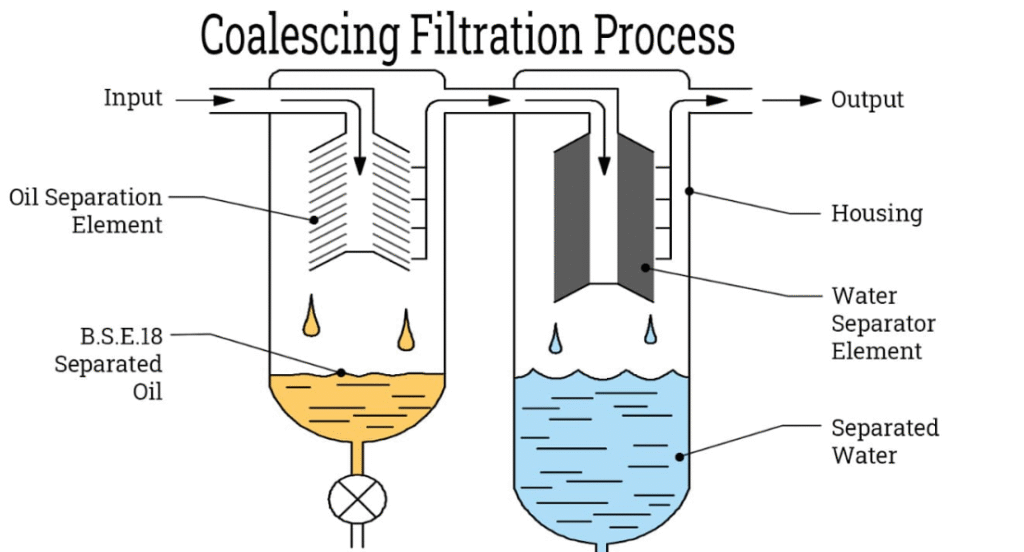

Multi-stage filtration removes particles down to 0.1 microns while maintaining flow rates suitable for production demands. Bag filters handle high dirt loads cost-effectively, while cartridge systems provide finer filtration with easy maintenance procedures.

Coalescing filters separate water from hydrocarbon streams, achieving dryness levels below 50 ppm. These units feature automatic drain systems that remove collected water without operator intervention.

Filter integrity monitoring uses differential pressure sensors to signal when replacement becomes necessary. Smart systems track usage hours and calculate remaining filter life based on actual operating conditions rather than generic time intervals.

Remote Monitoring Controls for Enhanced Safety

Wireless sensors transmit pressure, temperature, and flow data to central control rooms without expensive cable runs. Battery-powered units operate for years in remote locations, sending alerts via cellular or satellite networks.

Gas detection systems continuously monitor for leaks using infrared or catalytic sensors with response times under 10 seconds. Integration with emergency shutdown systems automatically isolates problem areas and activates ventilation equipment.

Cloud-based platforms provide 24/7 monitoring capabilities with smartphone notifications for critical alarms. Historical data analysis identifies trends that predict equipment failures before they occur, enabling proactive maintenance scheduling.

Professional Installation and Maintenance Tools

Precision Installation Equipment for System Setup

Getting PLG systems up and running correctly starts with having the right installation tools at your disposal. Torque wrenches calibrated to manufacturer specifications ensure proper fitting connections without over-tightening that could damage seals or threading. Digital angle meters help achieve precise alignment during pipeline installation, preventing stress points that lead to premature failures.

Professional-grade pipe threading machines create clean, accurate threads that seal properly with minimal compound. Hydraulic fitting assemblies require specialized crimping tools that deliver consistent pressure ratings across all connections. Laser alignment systems take the guesswork out of pump and motor coupling, reducing vibration and extending equipment life.

Welding equipment designed for PLG applications includes specialized electrodes and flux formulations that resist chemical corrosion. Pneumatic torque multipliers provide consistent bolt tensioning on large flanged connections, while ultrasonic thickness gauges verify pipe wall integrity before pressurization.

Diagnostic Tools for Equipment Performance Monitoring

Real-time monitoring prevents small issues from becoming expensive failures. Vibration analyzers detect bearing wear, pump cavitation, and coupling misalignment before catastrophic damage occurs. Thermal imaging cameras identify hot spots in electrical connections, insulation breakdown, and bearing overheating patterns that signal impending failure.

Ultrasonic leak detectors pinpoint pressure losses in systems operating under high noise conditions where audible detection fails. Digital pressure loggers track system performance trends over time, revealing gradual degradation that manual readings miss. Flow meters with data logging capabilities help optimize system efficiency and identify blockages or pump performance decline.

Corrosion monitoring probes provide early warning of material degradation in storage tanks and piping systems. Portable X-ray fluorescence analyzers verify material composition during installation and maintenance, ensuring compatibility with PLG chemistry requirements.

Preventive Maintenance Supplies for Long-Term Reliability

Smart maintenance programs rely on quality replacement components and consumables. O-rings and gaskets manufactured from PLG-compatible elastomers prevent leaks and contamination. Bearing assemblies with enhanced sealing systems resist chemical attack while maintaining lubrication integrity.

Filter elements designed specifically for PLG applications remove particulates and moisture that cause system damage. Corrosion inhibitors and biocides maintain product quality during extended storage periods. Calibration gases and reference standards ensure measurement accuracy for safety and quality control systems.

Specialized lubricants formulated for PLG environments protect pumps, compressors, and valve actuators from chemical degradation. Thread sealants and pipe dopes provide reliable connections that withstand temperature cycling and pressure fluctuations. Emergency repair kits containing compatible patches, clamps, and sealants enable rapid response to leaks and minor damage.

Quality documentation systems track maintenance intervals, part numbers, and performance history to optimize replacement schedules and inventory management.

Cost-Effective Procurement Strategies for PLG Supplies

Bulk Purchasing Programs for Maximum Savings

Smart procurement teams know that buying PLG supplies in bulk delivers serious cost savings. Volume purchases typically reduce unit costs by 15-40%, making this strategy essential for operations with consistent demand. Most suppliers offer tiered pricing structures where costs decrease significantly at specific quantity thresholds – often at 500, 1,000, and 2,500 unit breakpoints.

Consider consolidating orders across multiple facilities or departments to reach higher volume tiers. A manufacturing company with three plants can combine their monthly PLG supply needs to qualify for bulk pricing that individual sites couldn’t access. This approach also reduces shipping costs per unit and minimizes administrative overhead from processing multiple smaller orders.

Quarterly or semi-annual bulk purchases work best for non-perishable PLG components like fittings, gauges, and safety equipment. However, calculate storage costs and factor in inventory carrying expenses to ensure bulk savings exceed holding costs.

Supplier Partnership Benefits for Consistent Quality

Building strong relationships with selected PLG suppliers creates mutual benefits that extend far beyond basic transactions. Preferred supplier partnerships typically include priority allocation during supply shortages, extended payment terms, and access to technical expertise that can prevent costly operational issues.

Quality consistency improves dramatically when working with established partners who understand your specific requirements. These suppliers often provide dedicated account management, ensuring your needs receive personalized attention. Many offer value-added services like customized packaging, direct-to-line delivery, and specialized testing protocols tailored to your applications.

Partnership agreements frequently include performance guarantees and quality commitments that protect your operations from defective products. Some suppliers offer consignment inventory programs where they maintain stock at your facility, reducing your working capital requirements while ensuring immediate availability.

Inventory Optimization Techniques for Reduced Waste

Effective inventory management prevents both stockouts and excess carrying costs. Implement ABC analysis to categorize PLG supplies based on usage value and criticality. Class A items (high-value, high-usage) require tight control and frequent monitoring, while Class C items (low-value, low-usage) can use simpler reorder systems.

Set up automated reorder points based on historical consumption patterns and lead times. Safety stock levels should account for demand variability and supplier reliability. Fast-moving items like consumable parts need lower safety stock ratios, while critical components with long lead times require higher buffer levels.

Regular inventory audits identify slow-moving or obsolete stock that ties up capital. Consider implementing first-in, first-out (FIFO) rotation for items with shelf life considerations. Digital inventory tracking systems provide real-time visibility into stock levels and usage patterns, enabling data-driven purchasing decisions.

Long-Term Contract Advantages for Budget Stability

Multi-year supply agreements lock in favorable pricing and protect against market volatility. These contracts typically offer 5-15% savings compared to spot purchases while providing predictable budget planning capabilities. Price escalation clauses should be reasonable and tied to specific indices rather than open-ended increases.

Long-term agreements often include minimum purchase commitments balanced by supplier guarantees for availability and delivery performance. These contracts work best for high-volume, standardized PLG supplies with stable demand patterns. Include flexibility provisions for reasonable quantity adjustments based on business changes.

Contract terms should specify quality standards, delivery schedules, and performance metrics. Many agreements include annual price reviews and volume rebates based on total purchases. Consider partnering with suppliers who offer innovation sharing and technology updates as part of long-term relationships.

Conclusion

Having the right PLG supplies can make or break your industrial operations. From safety gear that protects your team to precision instruments that keep everything running smoothly, each piece of equipment plays a vital role in your daily workflow. The heavy-duty storage systems, pumping equipment, and maintenance tools we’ve covered aren’t just nice-to-haves – they’re essential investments that pay for themselves through improved efficiency and reduced downtime.

Smart procurement doesn’t mean buying the cheapest options available. Focus on quality suppliers who understand industrial demands and can provide reliable support when you need it most. Take time to assess your specific needs, compare warranties, and build relationships with vendors who truly get your business. Your PLG operations deserve equipment that works as hard as you do, so choose wisely and watch your productivity soar.

Abdullah Zulfiqar writes about technology in a simple, practical way, helping readers stay updated and make smarter decisions in an ever-evolving digital world.